Rubber & Plastic Industry: Payouts, Take-ups, Pullers, and Custom Applications

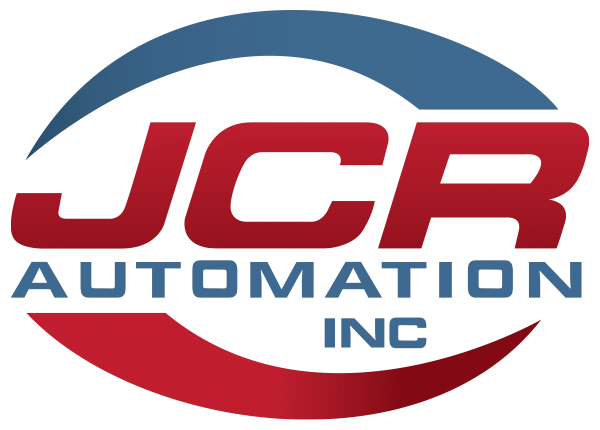

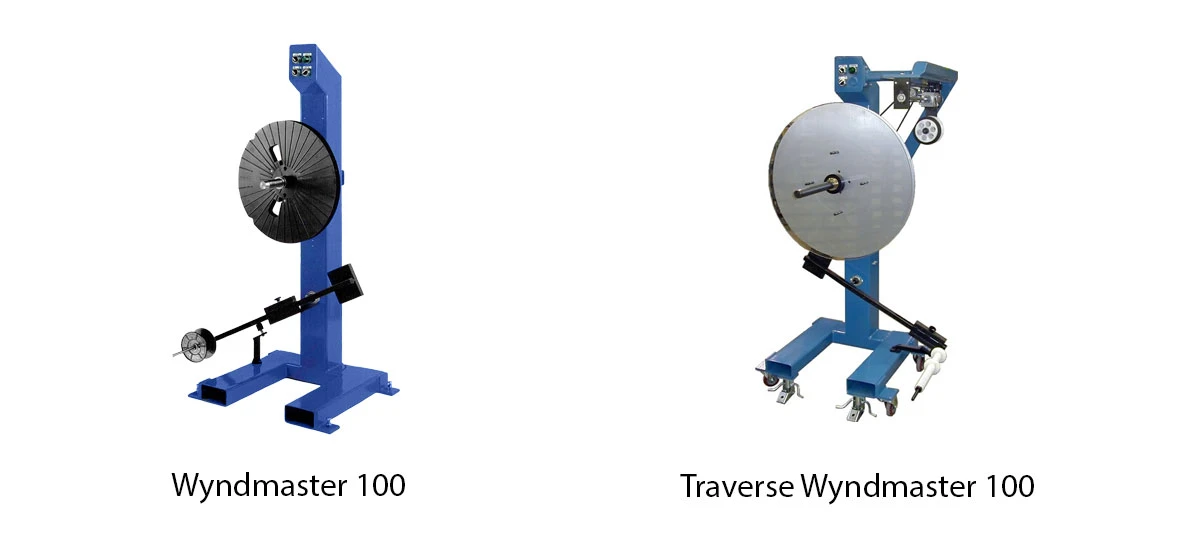

Payouts and Take-ups for any kind of rubber or plastic JCR provides a variety of machines for your continuous rubber and plastic products. Do you need a single or multi spindle winder? Pancake or Traverse Reels? Manual or Automatic reel transfer? JCR has a Wyndmaster machine to meet your requirements. Custom options at affordable prices JCR works with your engineers to provide custom options that perform consistently. We have pre-designed options for air-actuated mandrels, tapered reel cores, length measurement by encoder, coil weight measurement, and multi-wrap dancers, to name just a few. If you have unique specifications, we’ll put our experience to work for you and design a custom option that delivers.

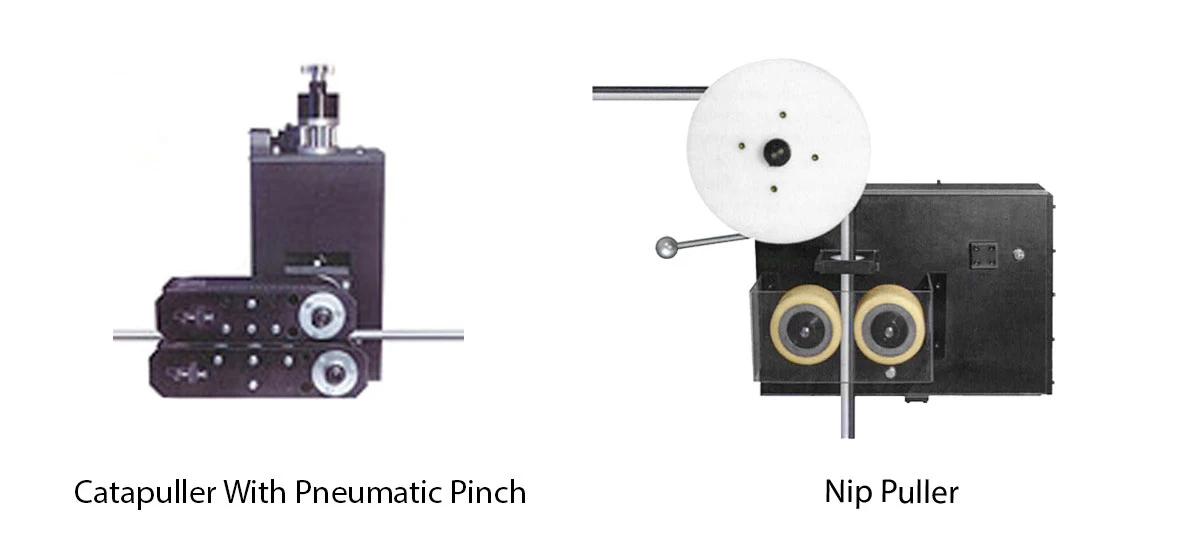

Standard and Custom Pullers The right puller can make your process run smoothly. Nip pullers and cat pullers are ideal for rubber and plastic products. They can be built with either master or slave functionality, and they can be integrated with other operations like product length measurement and cutters. The pullers pictured here have been used with automotive door trim, automotive tear strip, and profiled medical hose. We have also worked with products like steel overbraided teflon hose and silica fiber.

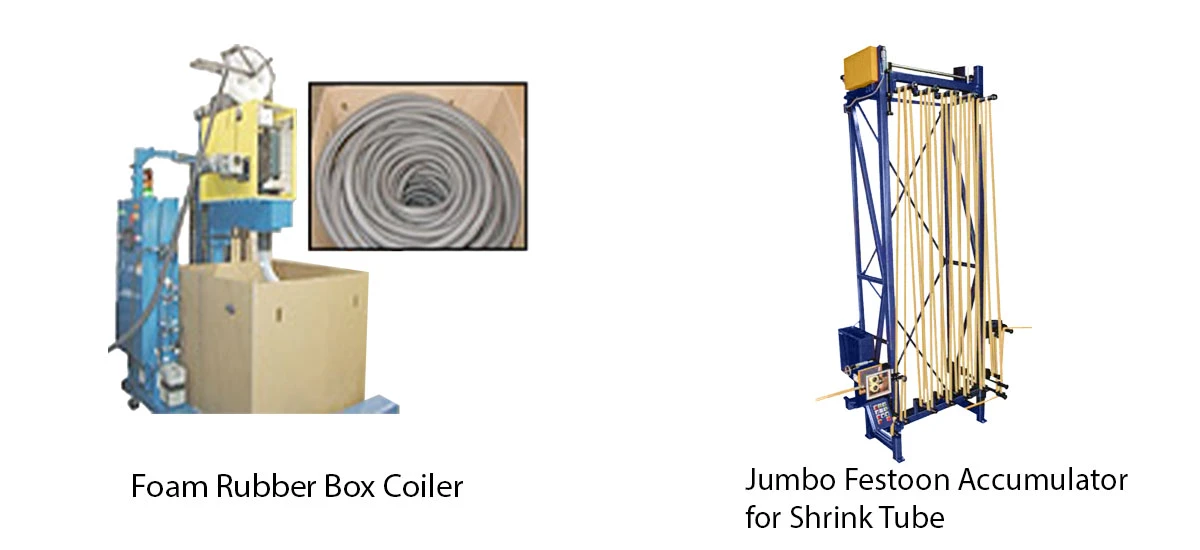

Rubber and Plastic Production Machinery Let JCR build your next production line for any plastic or rubber part. Material Handling Systems like the one pictured here use conveyors, pneumatic lifts, and turntables to move product seamlessly from one area of production to the next one. The water jet cutter is another version of our many cut to length machines. A jet of high pressure water provides a smooth cut. The pressure and vacuum gasket tester is a product qualification tester for large rubber gaskets. Looking to automate a labor intensive process? The foam rubber box coiler demonstrates how JCR can save manpower by automating a production or packaging process with a simple machine. The jumbo festoon accumulator can be used between two operations in an extrusion process. You can keep the extruder running while you change reels or keep a downstream process running while the extruder is off line.