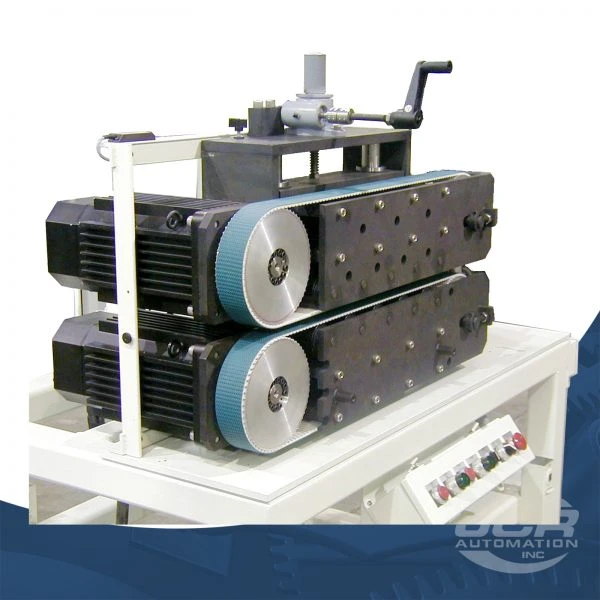

Pullers / Feeders

Standard Puller Designs: pullers and feeders are used in-line with strip processes to keep your product moving. These machines are currently being used in the production of stamped terminals, measuring tape, car door trim, medical tubing, shrink tubing, and silica fiber, to name a few. This equipment can be designed and built with any of the following operating parameters: Tension induction or reduction, master or slave operation, optional encoders for length or position feedback. Custom Puller Designs: pullers and feeders can also be customized for special operating conditions. The Tear Strip Puller consists of a nip puller with a pulley and control system designed for the customers process. The silica fiber catapuller was designed to work with high temperature fibers. Another catapuller with an encoder was integrated into a hose cut to length system. The catapuller feeds the product to a programmed length, after which a cutting operation is initiated.